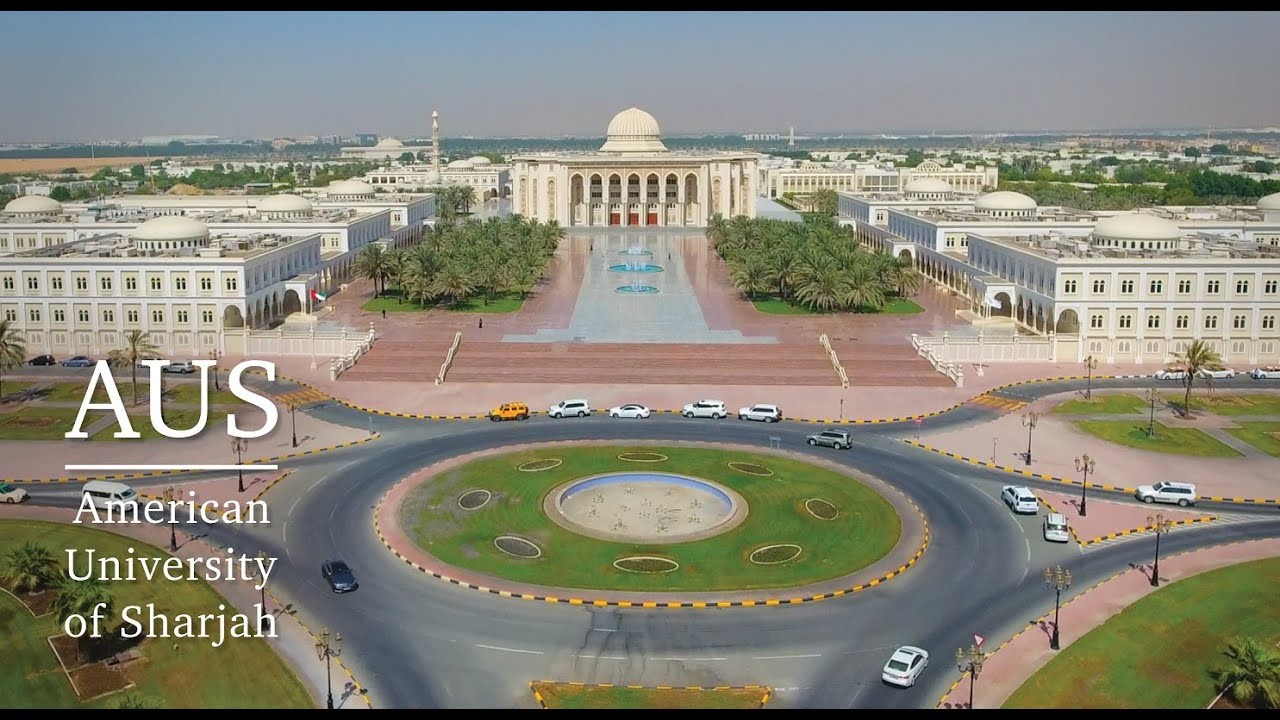

EGA collaborates with American University of Sharjah to re-use food waste to enrich manufactured soil made from bauxite residue

UAE’s largest industrial organisation, excluding gas and oil, Emirate Global Aluminium (EGA), has declared today a venture with the American University of Sharjah’s College of Engineering to study the beneficial qualities of re-using food waste to enhance the soil manufactured from bauxite residue.

The research aims to find if the intermixing of food waste, biochar and bauxite residue would give birth to a fertile soil easily applicable in vegetation and other production facilities.

EGA cooperates with the American University of Sharjah in the second phase of development within the duration of the three-year research project on the re-utilisation of bauxite residue, a by-product of the alumina extraction process.

Three extensive years of hard work resulted in the joining of two institutions to impose how food waste mixed with biochar is combined with rectified bauxite residue to produce a kind of commercial soil for greeneries and other purposes.

Biochar is a process of making charcoal, indigenous to the agricultural knowledge in the Amazon Basins.

This latest research shows that an internal process would be good for the environment and the economy, further enabling the UAE’s dream of utilising waste-to-energy products. The waste food and the red mud both would get a chance to be of ultimate use.

Abdalla Al Zarooni, the Vice President of Technology Development and Transfer at EGA, claimed: “We are always looking at solutions to reduce the waste streams of our industrial activities, in addition to supporting the UAE’s net-zero ambitions and landfill reduction goals. Following the technical breakthrough of EGA’s Turba process, which is the conversion of bauxite residue into manufactured soil, we look forward to our researchers examining the further economic and environmental benefits of using food waste to generate the required biochar for this manufactured soil.”

Except the by-products of food, bio-gas and bio-oil identified during the first phase of the research could potentially yield waste-energy uses.

There will be a giant innovation on a global scale if food waste can be recovered as designer biochar and passed on as bio-energy products.

This project could contribute immensely to the UAE’s goal of reducing waste-to-landfill by 75 per cent by 2030.

The facility will lower greenhouse emissions by multiplying local resources through R&D to contribute collectively to the upliftment of knowledge in the UAE.

EGA has also been chairing in-house research and collaborations with other institutions, including the University of Queensland’s School of Agriculture and Food Sciences.

At the beginning of this year, EGA declared that the company is to build a pilot plant in Al Taweelah to rectify bauxite waste and make soil products. The pilot plant will be the first of its kind in the world.

Dr Yassir Makkawi, the Project lead investigator and Professor of Chemical Engineering at AUS, commented: “Sustainable management of both industrial and food waste is one of the main challenges of governments as they seek to meet their targets for waste minimisation and reducing CO2 emissions. With environmental outcomes, an increasing concern of the public and strict regulations in place governing waste disposal and landfill, finding novel solutions is becoming more and more important. This project will now contribute to the UAE’s ability to successfully manage industrial and food waste in a way that has less of a detrimental impact on the environment than has traditionally been the case.”

Each year the UAE produces at least two million tonnes of wasted food and the primary research suggests that an estimated 20 to 40 per cent could be transformed into biochar and the same percentage into bio-energy products.

According to industry experts, almost 150 million tonnes of bauxite residue or ‘red mud’ is excreted each year globally, while only 2 per cent is used for productive purposes. If the bauxite residue is left untreated it cannot be utilised for anything since it doesn’t even support plant life. The UAE is a heavy exporter of soil products for agricultural purposes and greeneries.

Bio-energy substances can be used as a substitute for fuel oil or diesel in electricity generation since they are a low carbon energy source.

To fulfil its long term agenda of achieving net-zero, EGA has discovered renewed uses of other waste materials from its industrial units. The products include spent pot lining, a by-product of the aluminium smelting process that is now being reused as an optional feedstock and fuel by the UAE cement industry.

Other materials include carbon dust, utilised in cement manufacturing and dross that can be processed to recover aluminium. EGA endeavours to send zero process debris to the landfill.

The Bauxite Residue R&D Group under EGA has illustrated a dossier of supplementary novel applications which are still in a tender stage of evolution, with pilot-scale trials expected later.

source https://www.alcircle.com/news/ega-collaborates-with-american-university-of-sharjah-to-re-use-food-waste-to-enrich-manufactured-soil-made-from-bauxite-residue-80548

Comments

Post a Comment