SLM Solutions and Elementum 3D partner to develop stronger aluminium alloys for additive manufacturing

The additive manufacturing (AM) industry faces multiple problems during the research and development phase of any product for which it is trying hard to acquire better raw materials for the process. SLM Solutions and Elementum 3D have forged a partnership wherein the agencies will develop premium aluminium alloys 2024 and 6061 or aerospace grade 7050 and 7075 by 2023.

Currently, SLM announced the latest procurement of the NXG XII 600E along with a flexible manufacturing solution to deal with the difficulties faced by the AM industry related to building envelope limitation. Despite everything, the lack of preferable materials still prevails and is the most critical hurdle in producing precision-engineered AM components. The aviation industry puts forward a major requirement for AM products, but unfortunately, high-performing, crack-resistant materials are scarce. The components they order must have a perfect constitution since high-precision industries cannot accept defective pieces.

Again, the aerospace sector cannot survive without high-strength, versatile and corrosion-resistant materials. Thus aluminium plays a vital role in hoisting the particular industry, but pure aluminium cannot be utilised for such components because it is not that hardy. But aluminium alloys can be engineered to become stiff by amalgamating strong elements in the compound.

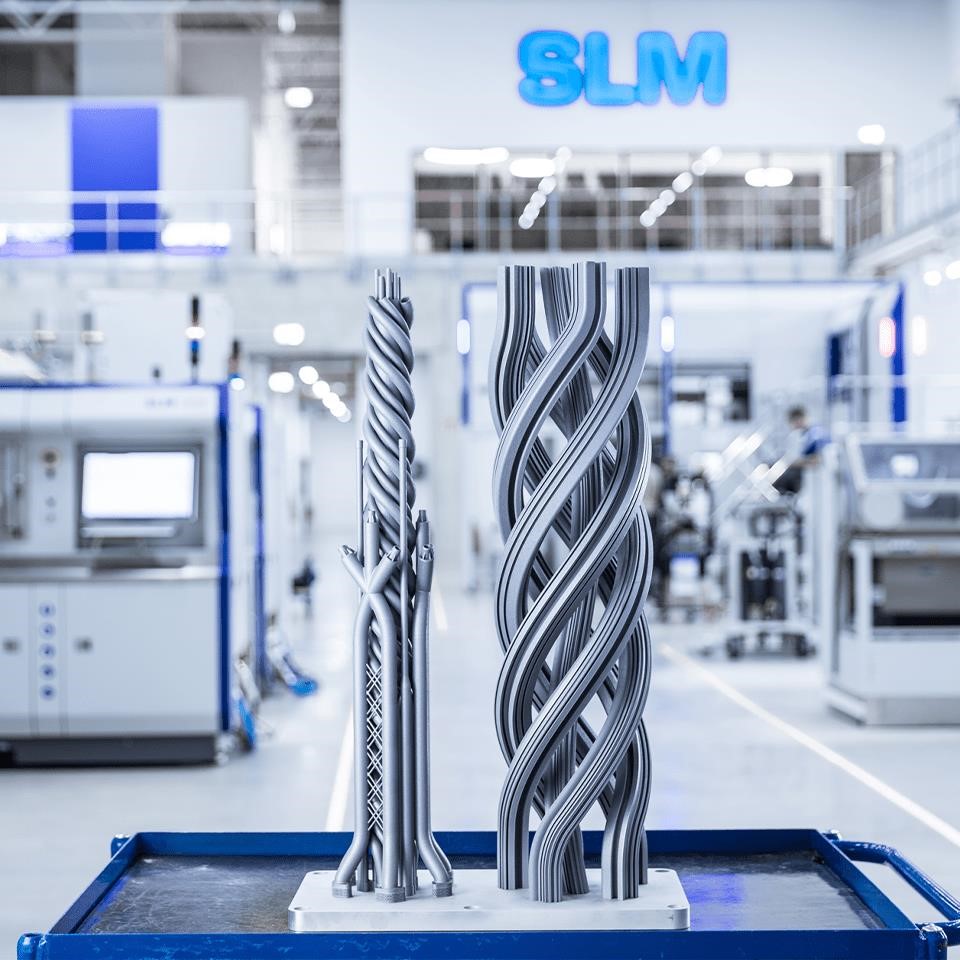

To commemorate their alliance, Elementum 3D acquired the exceptional SLM machine NXG XII 600 to generate state-of-the-art technologies and materials. Their idea was to create and develop Elementum 3D materials compatible with SLM machines, mainly the NXG XII 600.

This agreement benefits both companies as this coalition might produce better aluminium alloys or raw materials aligned with the machines manufactured by SLM Solutions.

Both companies are now working toward creating feasible raw material options for the 12-laser technology utilised to additively print end-user components for space or the aviation industry.

"This strong partnership will enable our goal of empowering our customers to achieve theirs. It will pave a path for an enhanced material portfolio enabling better-performing applications and new business cases. We look forward to this partnership achieving new heights in AM and accelerating the idea-to-production platform for our customers," said Sam O'Leary, CEO of SLM Solutions.

Jacob Nuechterlein, president and founder of Elementum 3D, highlighted the benefits of the agreement for additive manufacturing users: "We are pleased to announce this working agreement with SLM Solutions. With Elementum 3D's ground-breaking materials and SLM Solutions' leadership in production-sized printers for aluminium, we can offer a full solution to organisations ready to take their ideas to production."

SLM Solutions have enhanced systems that are customisable according to a customer's specific want, offering them a free choice of materials. Its flagship device NXG XII 600, is remarkably swift and introduces a new avenue in the additive manufacturing sector, permitting essential component production at a decreased cost per part. To top it all off, the NXG XII 600 now has an enhanced material catalogue from which one can choose freely.

source https://www.alcircle.com/news/slm-solutions-and-elementum-3d-partner-to-develop-stronger-aluminium-alloys-for-additive-manufacturing-87281

Comments

Post a Comment