In 1971, Aluminium Bahrain initiated its operations and produced the first aluminium ingot in the whole of the Gulf region, flagging the inception of a program of industrial diversification which was considered as bright and aspiring.

At present, GCC countries are listed proudly to be the home to some of the largest, ultra-modern, state of art technology-driven and environmentally friendly Aluminum production facilities. The success stories of primary aluminium production have made way for the commencement of many aluminium downstream industries and a variety of revolutionary ancillary businesses. Together the whole industry contributes to the region's economic affluence and adaptability.

The industry commenced from an elementary capacity of 120,000 tonnes of primary Aluminum per annum to now with six smelters world-class smelters, the Gulf region collectively produced 6 million tonnes in 2020.

However, 60% of the primary aluminium produced is exported to 65 countries around the globe, while downstream industries feed the local and international market with rolled, extruded, and aluminium wires and cables.

1971-2021, the five decades of the legacy of aluminium production has been a proud movement for all the former and current employees of the industry in the Gulf region for their hard work and achievement over the years.

_0_0.png)

Looking forward, the industry's precedence will be to work towards a comprehensive sustainable production mechanism to diminish the environmental challenges related to climate change while maintaining the highest safety and productivity levels.

Primary Aluminium in Gulf

The year 2010 showcased four new smelters Emal in Abu Dhabi, Ma'aden in KSA, Qatalum in Qatar, and Sohar Aluminium in Oman initiated towards boosting up their aluminium production, while at the same time, the pioneer smelter Alba in Bahrain and Dubal in Dubai conducted extensive modernizations to their plants.

This was the era from where the primary aluminium production in the Gulf region has more than doubled, and GCC becomes one of the leading hubs for aluminium production in the world.

The six aluminium smelters in the Gulf region changed the dynamics of global aluminium production.

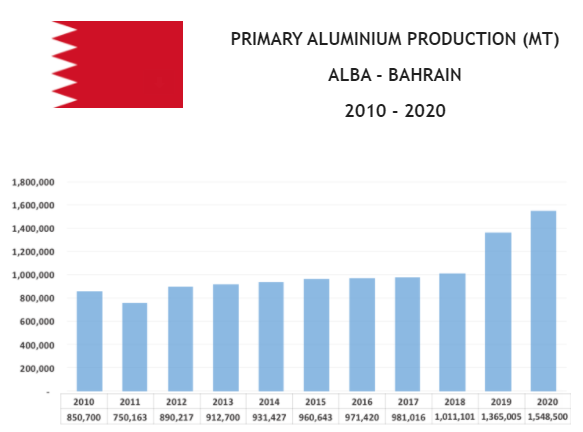

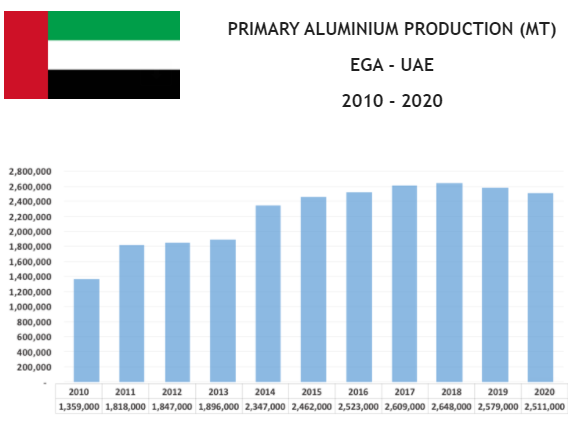

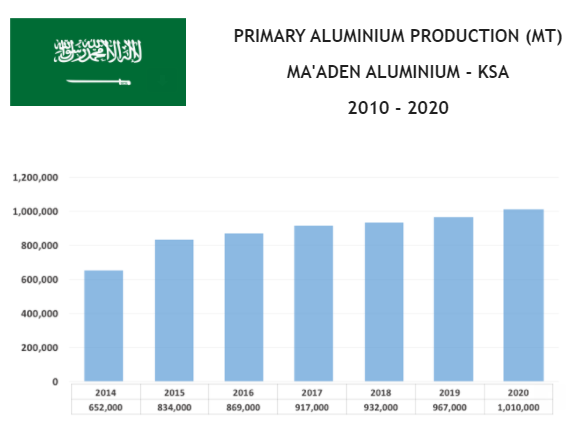

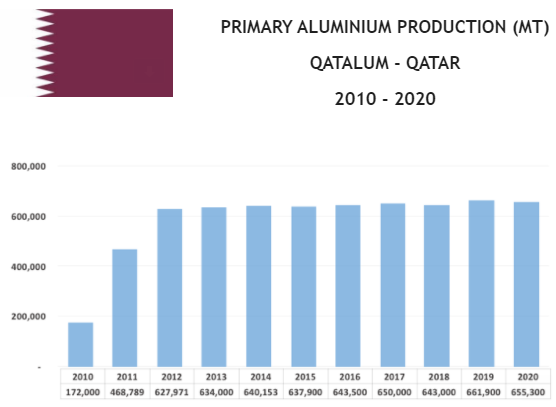

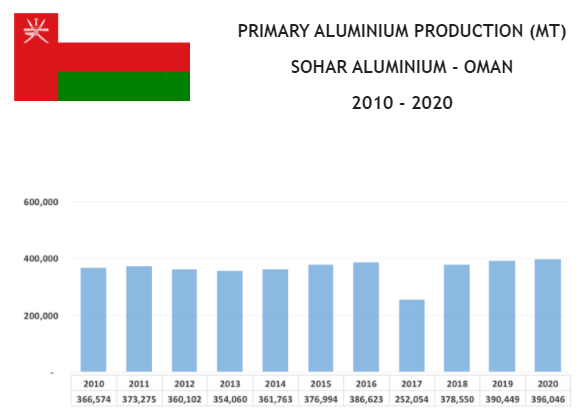

The below column charts denotes the primary aluminium output of each GCC country from 2010 to 2020:

Aluminium Bahrain (ALBA) – Bahrain

Alba is the world’s largest aluminium smelter ex-China with a production of more than 1.548 million metric tonnes per annum (mtpa) (2020). The Company’s shareholders are Bahrain Mumtalakat Holding Company B.S.C. © (69.38%), SABIC Industrial Investment Company (SIIC) (20.62%) and General Public (10%).

Alba Campus comprises six reduction lines, three power stations, four casthouses, and four carbon plants along with other ancillary facilities. In addition to primary aluminium production, Alba also produces 530,000 mtpa of high-quality calcined petroleum coke at its dedicated Coke Calcining Plant. Alba also yields 9.5 million cubic metres of potable water per annum from its dedicated seawater desalination plant.

Emirates Global Aluminium (EGA) – UAE

EGA is the world’s largest premium aluminium producer and the biggest industrial company in the UAE outside oil and gas. EGA is owned equally by Mubadala Investment Company of Abu Dhabi and Investment Corporation of Dubai. It is the largest company jointly owned by the two Emirates.

EGA’s metal is the biggest made-in-the-UAE export after oil and gas, bringing in billions of dollars of export revenue each year contributing to the diversification of the national economy. It is also said that 4% of the world’s aluminium production or almost half of the aluminium produced in the Gulf Cooperation Council, is produced by EGA, which means approximately one in every 25 tonnes of aluminium is UAE-made.

EGA operate aluminium smelters in Abu Dhabi and Dubai, an alumina refinery in Abu Dhabi, and a bauxite mine and associated export facilities in the Republic of Guinea.

Ma’aden Aluminium –KSA

The perception behind Ma’aden’s drive into aluminium production is to maximize the minerals and metals value chain. Ma’aden’s ‘mine-to-metal’ vision resulted in the development of a new home-grown and sustainable industry and transfer of know-how associated with it, and positioning Saudi Arabia as a supply-side player in a global industry with strong prospects to grow and diversify in the future.

In 2009, Ma’aden established a joint venture with Alcoa, the world’s third-largest aluminium producer, to build the world’s most efficient and integrated aluminium complex in Saudi Arabia. Ma'aden’s Fully Integrated High-Efficiency Aluminium Production Complex involves the development, design, construction and operation of plants in two sites that are integrated into a single mine-to-metal network.

The $10.8 billion (SAR 41 billion) project includes a bauxite mine, an alumina refinery, a smelter, a casthouse, a can recycling unit and the world’s most advanced Rolling Mills. Ma'aden’s Fully Integrated High-Efficiency Aluminium Production Complex, and is the largest and most efficient vertically integrated aluminium complex in the world. Its products, aluminium of the highest international standards, are sold to both domestic and global markets and are encouraging the development of additional downstream aluminium-based industries in Saudi Arabia and neighbouring countries.

Qatalum – Qatar

Qatalum operates an aluminium smelter in Mesaieed, Qatar, approximately 40 km south of Doha and its facilities include a carbon plant, a reduction plant, a casthouse, port and storage facilities as well as a captive power plant. Through the efforts of the organisation’s dynamic and diversified workforce made up of over 40 nationalities, Qatalum contributes to the industrial diversification of the State of Qatar while creating a future of sustainable development.

Qatalum produces more than 600,000 tonnes of high-quality primary aluminium products per annum. Its value-added extrusion ingots and foundry alloys meet the stringent quality standards of the global customer base. Qatalum aluminium is used in a variety of industries including automotive, construction, engineering and consumer goods manufacturing, its metal is used in shaping the modern world.

Qatar Aluminium Limited is owned equally by Hydro Aluminium of Norway and Qatar Aluminium Manufacturing Company (QAMCO) of Qatar.

Sohar Aluminium – Oman

In September 2004, Sohar Aluminium was formed to undertake a landmark Greenfield aluminium smelter project in the Sultanate of Oman and is jointly owned by OQ SAOC, Abu Dhabi National Energy Company PJSC - TAQA and Rio Tinto.

By implementing decades of industry insight in its design, specification and construction Sohar Aluminium has been created to ensure efficiency, environmental protection and the utmost safety of its workforce. The smelter has an annual production capacity of 390,000 tonnes of high-quality Aluminium.

Omanisation, which currently stands at 76% of its workforce, is a driving force within the organisation. The development of its young employees is paramount and with that in mind, Sohar Aluminium has its own internationally recognised training centre which gives every employee the opportunity for further learning.

source https://www.alcircle.com/news/the-gulf-aluminium-industry-a-legacy-of-5-successful-decades-with-6-aluminium-smelters-68897

Comments

Post a Comment