“As a group focused on design, production, and maintenance of equipment, we see innovation as a way to make our solutions more efficient and competitive” - Cédric Schmuck, Director of the Aluminium Division within REEL

REEL is an industrial group specializing in complex lifting and handling systems as well as integrated systems solutions. It is using the present sanitary crisis to reinforce an Industry 4.0 approach in its different markets: Nuclear, Aluminium, Aeronautics, Offshore, etc. Many technological opportunities appear in the field of equipment, maintenance, or even design methods. Cédric Schmuck, Director of the Aluminium Division within REEL, in an interview with AlCircle said, as a group focused on design, production, and maintenance of equipment, we see innovation as a way to make our solutions more efficient and competitive. He also said that although the corona crisis has weighed on the aluminium production, but that should not impact the companies so much, owing to the lower input costs such as electricity, carbon and alumina.

To know more what Mr Schmuck shared with AlCircle, read on the interview below.

AlCircle: How are you coping with the corona crisis?

Mr Cédric Schmuck: Through our activities in China, we decided to take very early measures to protect our employees and partners, limiting travels and organising social distancing and home-office already in February. We are now entering everywhere in a second phase, with measures to gradually reduce lockdowns, still with restrictions on movement and assembly. But the virus is still there and we will all continue to apply, for a still unknown period, the rules of distancing, protection and hygiene.

Like every convinced European, it pains me to see border police and barriers again at the heart of the EU. However, when opening the borders, a coordinated approach is needed so as not to jeopardise the progress we have made in the fight against the virus, for which we all have sacrificed our normal lives to some extent in the past few weeks.

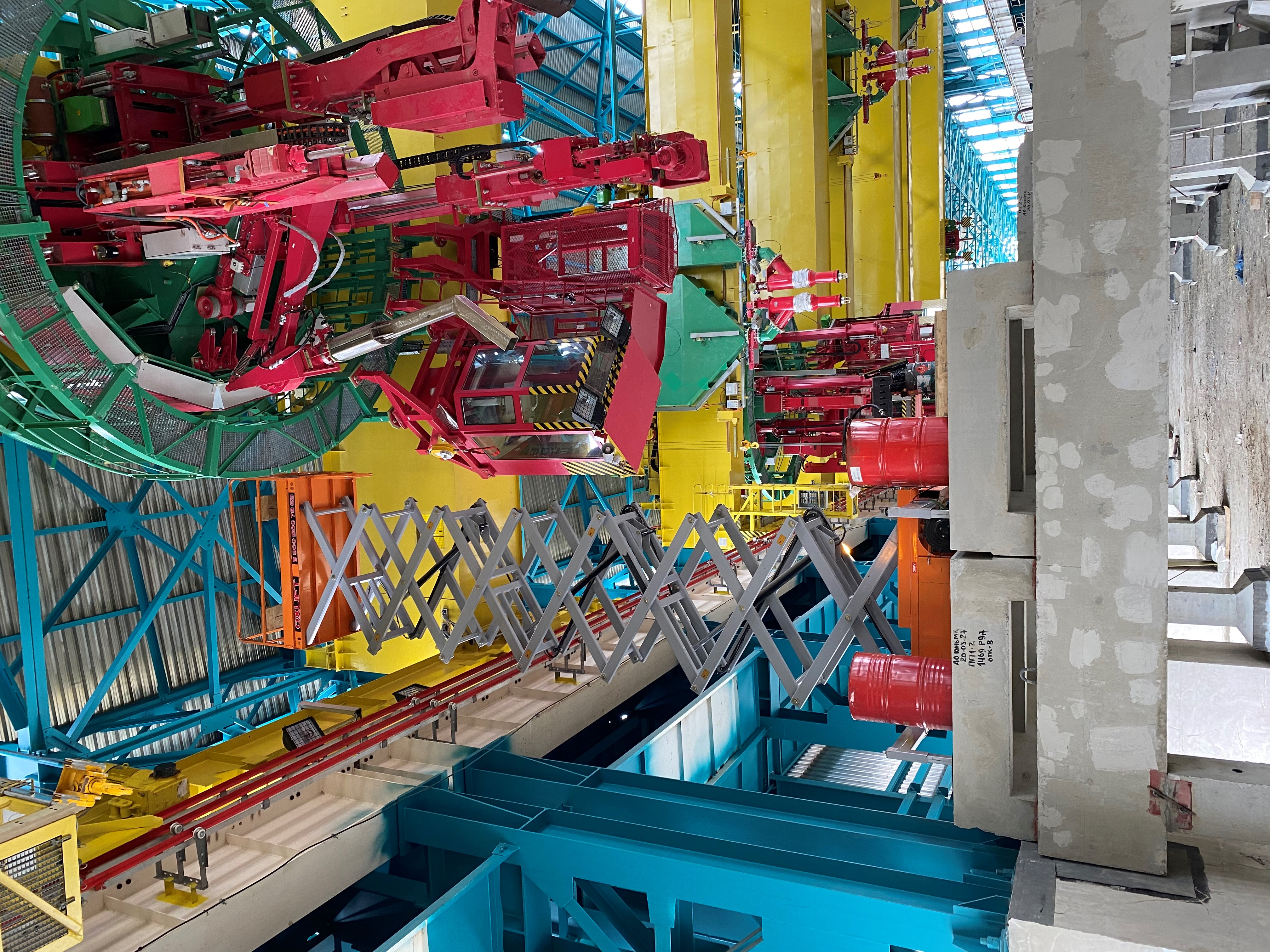

We would like to thank all our employees for their professionalism and their positive attitude during this period. We are extremely proud on the way all our employees have reacted and adapted to the crisis, including on very remote site works in Norway for Hydro Husnes, in Siberia for Rusal Taishet Aluminium, and in Bahrain for the Alba harbour extension.

AlCircle: More specifically, how do you see the coming times?

Mr Cédric Schmuck: In this new phase, we will keep home-office in place as much as possible. People whose work requires it or who have difficulties will be able to return to the office, full-time or punctually. Everything has been put in place to ensure the safety of the employees present at our different sites. Our factories have resumed work gradually, again with the implementation of all the necessary safety conditions. Regarding our service activity, a majority of our teams are now working full time on the sites of our customers.

AlCircle: What does the corona crisis mean for the Aluminium industry?

Mr Cédric Schmuck: The corona crisis has many tragic and serious influences. Some companies have announced aluminium output reduction because of the lockdowns due to coronavirus: Alcoa at the Intalco smelter in Washington State, Rio Tinto at the Tiwai Point smelter in New Zealand with production continuing on three lines; Argentina's Aluar has temporarily closed 50% of its capacity and Chinese aluminium smelters have cut their annual production capacity by up to 340,000 tonnes. However, many producers’ balance sheet should not be impacted too much, partly because the input costs such as electricity, carbon and alumina have also tumbled down, supporting their margins.

Let us remain confident, our multi-sector activity has enabled REEL in the past to rebound several times during various crises. Even if this is incommensurate with the previous ones, we will all be able to face it together with the agility and resilience that characterizes us.

One topic, however, is definitely positive and is currently taking place on a completely different level: working from home. In the wake of the pandemic, numerous companies and associations have quickly realized that infrastructures must be established immediately to create the necessary conditions for decentralized and networked work. Hence the 'positive' assessment of this aspect of the current situation: corona is accelerating digitalization.

AlCircle: What is your personal opinion?

Mr Cédric Schmuck: I think that social interaction will change through home-office. We are at home with our families for longer periods of time and can organize our work more flexibly than in rigid schedules. Creativity is increased and more flexible design condition releases new energies. However, working successfully in the home office means good planning and structuring of daily routines. The working world and the private world must be strictly separated.

Our relation with our client is also impacted in a positive way. Through this crisis, our teams have demonstrated heavy commitment towards our customers, being sometime the last man staying at site to support their project and now remotely using latest technologies.

AlCircle: REEL has embarked on an Industry 4.0 approach for several years. How does this translate concretely?

Mr Cédric Schmuck: As a group focused on design, production, and maintenance of equipment, we see innovation as a way to make our solutions more efficient and competitive:

- Machine monitoring by smart sensors and new instrumentation devices to detect low-signal and avoid failures;

- Collection and analysis of production data on complete facilities that we have delivered to improve control of operations;

- Use of virtual reality in design and client review of our equipment. These devices allow our designers to verify directly with customers the relevance of offered technical solutions, and our maintainers to better prepare their interventions;

- Development of mobility solutions in order to provide our maintenance personnel, on tablets or smartphones, with as much data as possible, as close as possible to the equipment to be maintained.

We are also looking to further push the automation of the equipment we deliver and make them more autonomous.

This goes as far as the development of robotic solutions, such as in aeronautics where we have drilling technology, which can be mounted on a robot and capable of adapting the cutting parameters in real time according to the layer of material traversed.

AlCircle: This approach notably impacts your relationship with your customers in terms of maintenance service. How has it changed your offer?

Mr Cédric Schmuck: Maintenance methods are evolving with the availability of an ever-increasing amount of data. Thanks to the tools that we have developed to analyse the production data of our installations, we can support time loss reduction and continuous improvement initiatives for customers. Our maintenance teams can also optimize their maintenance plans and develop predictive maintenance.

In general, we seek to take advantage of all new technologies to make maintenance more responsive and more relevant. For example, on a very large site of one of our customers, we have installed on a fleet of equipment, real-time acquisition units making it possible to record the GPS location as well as actual quantities. This maximizes usage, anticipates failures and facilitates access for production and maintenance operations.

AlCircle: What are your challenges both internally and vis-à-vis your customers in the context of the deployment of Industry 4.0? How do you deal with it?

Mr Cédric Schmuck: Data analysis necessarily implies compliance with a policy and the implementation of flawless technical means for the transmission and protection of data. We also need to adapt in our businesses, with the strengthening of skills in IT development, analysis and data processing. In the maintenance trades, we invest in methods and training to integrate data analysis into the orientation of maintenance choices.

Finally, we are permanently monitoring to detect relevant technologies and be able to integrate them, very early on, in our equipment or our maintenance services. Our target is to bring innovative breakthrough solutions by drastically reducing our client’s investment and operation costs.

Our latest innovation called REEL VisionTM provides the foundation for connected worker programs. This fully rugged head-mounted device, which snaps into safety helmets, can be used with safety glasses or corrective eyewear. It can be used in wet, dusty, hot, dangerous and loud industrial environments. It is an industrial dashboard: there when you need it and out of your way when you do not. We are very excited to bring this innovation to the market.

Together towards performance!

source https://alcircle.com/interview/detail/55806/as-a-group-focused-on-design-production-and-maintenance-of-equipment-we-see-innovation-as-a-way-to-make-our-solutions-more-efficient-and-competitive-c

Comments

Post a Comment