QuesTek Innovations develops new aluminum alloy for additive manufacturing capable of high temperature performance

QuesTek Innovations LLC, a US based leading Integrated Computational Materials Engineering company has developed a new aluminium alloy for additive manufacturing. The alloy is capable of high-strength performance at 200 to 300 degrees C in the as-built condition. According to the company it is the first aluminium alloy powder capable of meeting those requirements without the need for heat treatment.

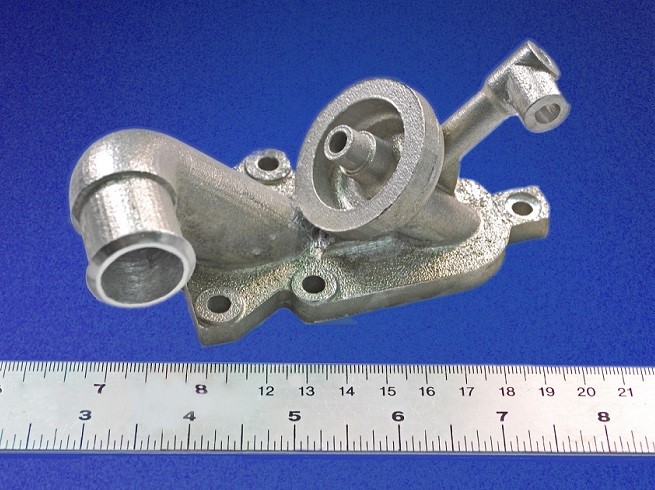

The new aluminium alloy will help in printing lightweight precision components like heat exchanger parts requiring internal cooling channels, which are not possible with conventional manufacturing method.

Commenting on the development, Greg Olson, QuesTek chief science officer, said, “The accelerated design and development of a printable aluminum alloy capable of meeting so many current needs … will enable concurrent design of material composition and component geometry. Based on our internal test results, we see broad application of this material in manufacturing components for aerospace, satellite, automotive, and high-performance racing.”

The company will collaborate with the German Aerospace Center (DLR), which will print demonstration components for aeronautics and space applications using the alloy and prepare a performance brief for European aerospace manufacturers so that the parts can be used for commercial manufacturing.

source https://www.alcircle.com/news/questek-innovations-develops-new-aluminum-alloy-for-additive-manufacturing-capable-of-high-temperature-performance-49501

Comments

Post a Comment